Sales of the new crossover SUV Mazda CX-8 has commenced on December 14.

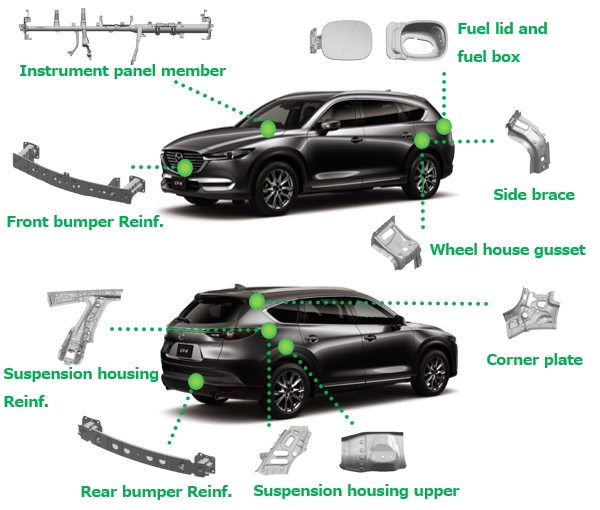

The new CX-8 incorporates a Futaba Kogyo steering member (instrument panel member), one of the Company’s key products, as well as our front and rear bumper reinforcement, suspension housing reinforcement, fuel lid and fuel box, and other body shell parts.

With the goal of achieving vehicle weight reductions, we diversified our use of high-tensile-strength steel plate materials and implemented advanced press molding techniques to achieve stable product quality.

Furthermore, we implemented steady improvements such as enhancing yield rates to save resources and reduce costs, enabling us to make significant contributions in terms of environmental conservation.

*The part name “Reinforcement” is shown as “Rainf” for short.

After the bingo game, it was BBQ time!

Food trucks were also ready, such as Takoyaki(octopus dumplings), pork miso soup and the local brew. We had plenty of time to cultivate a friendly relationship between employees. Some are participated with family and it was fun event for family member as well.

There was a lot of nature around there so it was a nice place to spend time in. We were relieved daily stress. We believe this event would make us motivated.

Mr.Tsuboi, the chairman of Hiroshima Shinkin Bank which is our main bank and Mr.Yoshida, the president of Futaba Kogyo held the top meeting.

It has past just 40 years since Mr.Yoshida taken up his post. He invited Mr.Tsuboi to express thanks for supporting our stable company-operation and employment.

We accepted interns just as last year to let them experience to manufacture stamping parts for automotive.

The 3 interns of university students tried demonstrating a series of work processes from development to manufacture.

As one of training, they experienced bench-marking (compare/analyze our products and ones of rival companies) of a fuel lid.

They learned importance through development training on how to distinguish excellent points (product shape, function, productivity, etc.) and how to differentiate them from other rival companies in response to customer needs.

Here is a comment from the intern participated, I saw each and every employees worked in line with the policy of “Creating a system that precludes the possibility of defects “. It was a valuable experience for me to get to know difficulty and seriousness of working in a society.

left)Learning a die structure and how to check it

right)Measuring outer gap of a fuel lid

Mazda Vehicle Exhibition and Test-drive Event and Hoyu-kai Festival was held in Nishinoura area of Mazda Hofu Plant on Sunday, July 23. It was the project to commemorate the 35th anniversary of opening Mazda Hofu Plant.

Mazda, together with Hoyu-kai and Yamaguchi Mazda, planned various events in order to entertain the Hoyu-Kai member companies and their family. The events included test-drive, performances on stage,“Monodzukuri”experience workshop and others.

At the line side of the Mazda assembly plant, each member company introduced that their products were used in which part of the complete vehicle. The visitors also enjoyed touring the member companies’ sites by doing stamp rally. A total of 2,156 people brought more excitement to the festival than usual.

Our Hofu plant employees supported the festival through selling flavored shaved ice, which was very popular to the visitors. Many of our staff and the family from headquarters and other plants joined the event and boosted the festive mood.

※Hoyu-kai: an association of Mazda’s partner companies in Hofu area

Blind speed-drinking contest, Train“Choruru”-Yamaguchi Pref.’s mascot- , Big jump rope contest

Futaba Kogyo, as one of the business partners, set up a booth along the“Monodzukuri ROAD”, or an arcade featuring craftmanship and manufacturing, where visitors can enjoy exhibition and workshop.

Under the common theme of“Monodzukuri Experience”, we planned activities which can entertain visitors, especially children. They enjoyed press work experience by making steel badges and lotteries to win original balloons.

Our booth ended in great success with more visitors than last year. We appreciated that so many visitors had a good time with us.

Toward the 100 anniversary of Mazda foundation, Futaba Kogyo, as a supporter of Mazda brand, never stop challenging to go further by developing and cherishing integrity of our employees.

On May 27th, we held the 37th sports festival at a ground in Sakurae plant.

Total 97 of paticipants from all of our plants. It was organized by the planning committee members from each departments and we enjoyed to play ground-golf and tennis.

For lunch, we prepared not only BBQ as usual but set a food stall of tako-yaki (octopus dumpling, which is popular street food) and ice cream. It was well-received enough by everyone to make a long queue in front of it.

At daily situation, each employee has less chance to comunicate others in different plants.

It was great opportunity for everyone to share a special time, play sports and have lovely meal.

It was also great chance for our new employees who just joined to the company in April to adopt theirself to new environment.

In the season of cherry blossoms, Futaba Kogyo has hired 20 people of fresh and energetic new employees. (4 technical, 16 engineer) The welcoming ceremonies was held in April 3.

President and Director, Mr.Yoshida sent them a message as follows and new employee was listening with attention every single words.

It’s important to clearly understand our policies, philosophy and conduct code.

I hope for your happiness. I want you to accumulate good deeds by devoting yourself in the spirit of service to others instead of being self-centered like you think only of own convenience.

Several sort of trainings and education is to be held for 10 days such as general manners and attitude, safety and quality and welding method. (The assigned location will be decided after practical training on each plants until end of May)

With passionate newcomers, we commit ourselves to making a fresh start in the upcoming term.

We got a request from Thai Summit Eastern Seaboard Autoparts Industry Co., Ltd. (TSESA) and sent our technicians to their plant in Thailand to conduct the improvement activity jointly, called “A-ABC activity” (ASEAN-Achieve Best Cost).

The A-ABC activity is to strengthen competitive edge of suppliers. For the purpose of making an ideal condition realized, we grasp and canalize actual condition, then discover and implement improvement plan.

The activity is held twice a year and in accordance with a theme given.

Here is an interview with one of member participated, from Engineering dept. Body Assembly Engineering sec.

Q/ Please tell us what you did for this activity.

A/ At TSESA, workers there had a problem with a weld robot. It didn’t weld on right point so they had to adjust afterward by hands. To weld without problem, correct set-up of weld condition is required.

As a result of our analysis, we found that the cause of trouble was wrong set-up.

However they were adjusting weld every time without fixing set-up of the robot.

So we educate them how to set-up weld condition.

Q/ What was a specific difficulty you had?

A/ First of all, it was language.

It was so tough to explain and let them understand.

They have a poor investigation ability. It seemed that they took temporary substitute only when troubles occurred.

Local workers and we needed lots of time to investigate a real cause of trouble and take measure for it.

Q/ What did you learn from this activity?

A/ We usually educate basic rules include weld condition at the stage of preparation for MP. However they did not follow these rules properly and this matter was cause of trouble.

We had to think seriously how to let them understand that following basic rules is essential.

Q/ How do you benefit to your future work from the experience?

A/ For Basic Manufacturing, it’s important to study basics at first, then practice these basics properly.

Simply we should do what’s expected as expected. I will hand these down to younger staff working with. It was first time for me to go overseas business trip. I learnt so many things from this experience and gained confidence in myself. Based on the experience, we keep improving quality level and productivity.

Working for the activity

The Mazda Ekiden Road Relay was held as part of the 24th Love Hofu Campaign at the Mazda Motor Corporation Hofu Plant (in the Nishinoura district).

A total of 100 teams from Yamaguchi Prefecture and beyond took part in the event, and young Futaba Kogyo employees participated in and this was the 4th participation for us.

Futaba team enjoyed and completed the race and made 59th-place finish.

Through the event, we were able to communicate local people, also we believe our teamwork has become more intense.